From Waste to Worth: Rethinking biosolids management using Onunda’s advanced thermal conversion technology

Biosolids management is at a real pivot point for the water sector.

Across utilities globally, rising costs, tightening regulation, and increasing carbon pressure are putting traditional biosolids routes under strain. Incineration and land spreading are becoming harder to justify financially, environmentally, and socially, particularly as contaminants like PFAS and microplastics come under sharper scrutiny.

At the same time, biosolids are often treated as a pure disposal problem, despite containing recoverable energy, carbon, nutrients, and water. The challenge, and the opportunity, is how to unlock that value in a way that is affordable, scalable, and future-proof.

This is the space Onunda is working in.

An end-to-end thermal platform for wet wastes

Onunda has developed an advanced thermal conversion platform designed specifically for high-moisture biosolids and agricultural slurries.

Our system processes wet feedstocks, typically around 85% moisture, without the need for energy-intensive pre-drying. This is a critical advantage when dealing with sludges, slurries, and mixed organic wastes.

The platform integrates four core process stages:

Hydrothermal carbonisation of wet feedstock

Mechanical separation of liquid and solid fractions

Low-temperature drying using recovered waste heat

Indirect rotary kiln pyrolysis with flexible operation

This configuration allows treatment at controlled temperatures while minimising unwanted by-products. The use of a rotary kiln also provides operational flexibility, enabling switching between pyrolysis and gasification depending on feedstock characteristics, regulatory requirements, and target products.

Flexibility matters, as utilities need systems that can adapt over time as regulations evolve and waste streams change.

Three valorised products, not one disposal route

Rather than a single output, the Onunda process produces three valorised products:

A stabilised biochar containing recoverable nutrients

Recovered thermal energy from process gases and waste heat

A sterilised, nitrogen-rich liquid fraction containing dissolved organic carbon

The liquid fraction can be reused within agricultural systems during growing seasons or routed to anaerobic digestion during winter months, improving whole-system nutrient and energy circularity.

The solid fraction is converted into biochar that can be tailored for different end uses. Biochar produced from agricultural slurries is suitable for fertiliser applications, while biochar derived from biosolids is being developed for construction and infrastructure uses.

Built, commissioned, and operating

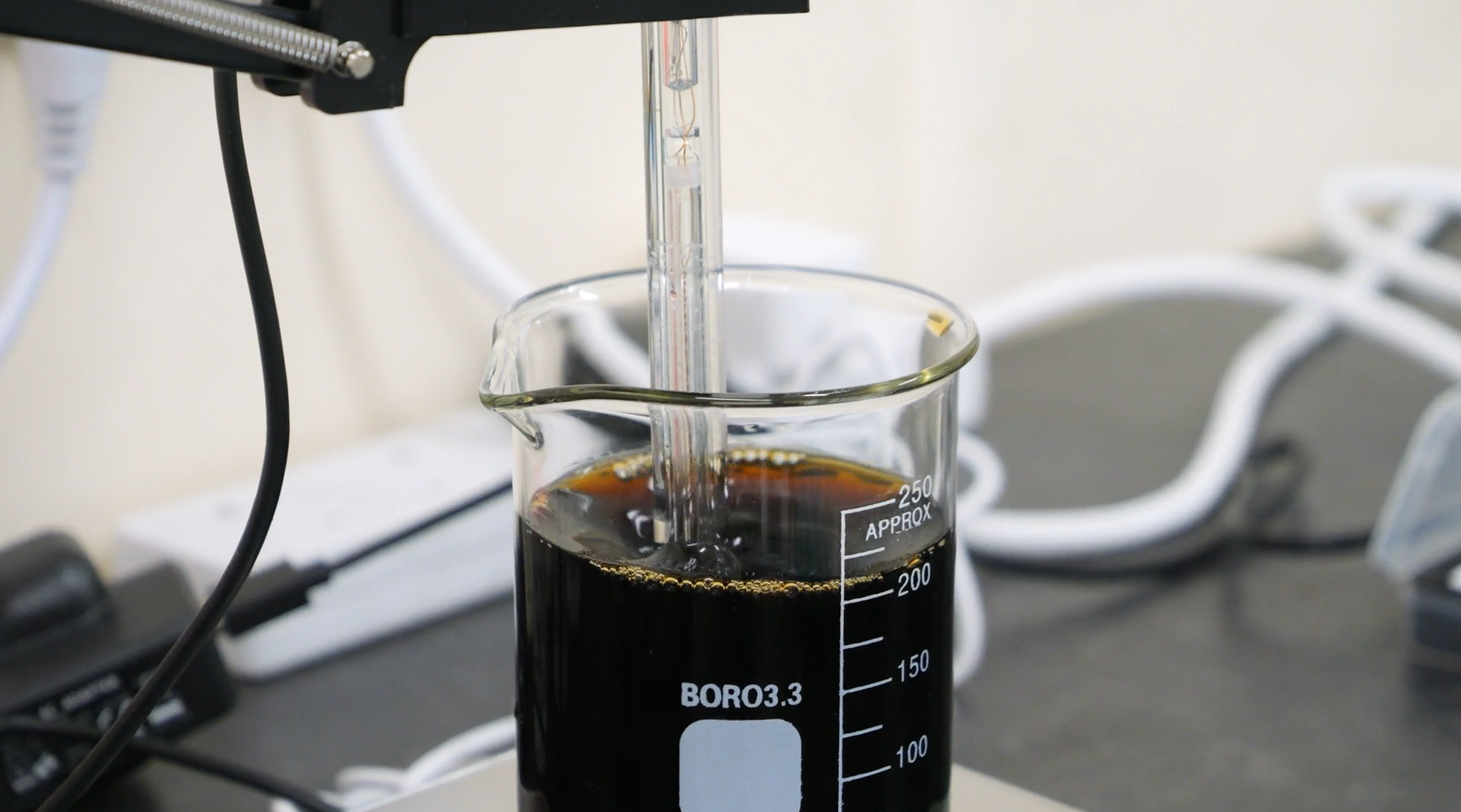

In 2025, Onunda completed the build and commissioning of its pilot plant in Carlisle, United Kingdom, in just nine months.

The facility is now processing two distinct waste streams:

A mixture of cow slurry and broiler chicken manure, converted into fertiliser-grade biochar

Biosolids from advanced anaerobic digestion, converted into biochar intended for construction applications

This marks a shift from concept validation to operational reality.

Designed for decarbonisation and resilience

The Onunda platform is designed to operate without fossil fuel heat input. Pyrolysis gas generated within the process is used to supply thermal energy, while high-grade waste heat is recovered for drying stages. This significantly reduces scope 1 emissions and exposure to volatile energy costs.

Beyond emissions reduction, the process supports mitigation of emerging contaminants, including microplastics and PFAS, while enabling long-term carbon storage through stable biochar formation.

Onunda is pursuing full carbon auditing of feedstock, process performance, and end use, with the objective of enabling verified carbon credits for organisations seeking to invest in durable decarbonisation pathways.

From disposal liability to circular asset

At its core, Onunda is about changing how the water sector thinks about biosolids.

Instead of treating them as an unavoidable liability, our approach turns biosolids into a circular asset that delivers energy recovery, nutrient recovery, and long-term carbon value.

Since receiving the WEX Global Award for Innovation in Decarbonising, Onunda has progressed rapidly from early validation to a working pilot platform. The focus now is on scaling the technology for commercial deployment in partnership with utilities, infrastructure operators, and like-minded investors.

This is about delivering a practical, affordable route toward a circular and regenerative future, one that works within the real constraints utilities face today.